Temperature-controlled drug shipment has come into an era of scientific revolution. Material science innovations and electronic monitoring are setting new benchmarks for pharmaceutical safety and efficacy. Studies indicate that phase-change materials (PCMs) maintain heat stability for over 72 hours in transit, reducing the incidence of vaccine spoilage by up to 95% (Journal of Thermal Analysis and Calorimetry, 2024). Today’s IoT sensors enable real-time, continuous tracking of environmental conditions, mitigating 30% of drug losses that occurred from temperature changes in the past. Such technology is particularly precious for biologics like insulin and mRNA vaccines, where exposure to inappropriate temperatures for a few seconds can destroy therapeutic effectiveness. Predictive analytics powered by AI also revolutionized the field of cold chain innovation, where analytics streamline distribution channels and eliminate time lags.

Innovative Materials Enhancing Cold Chain Durability

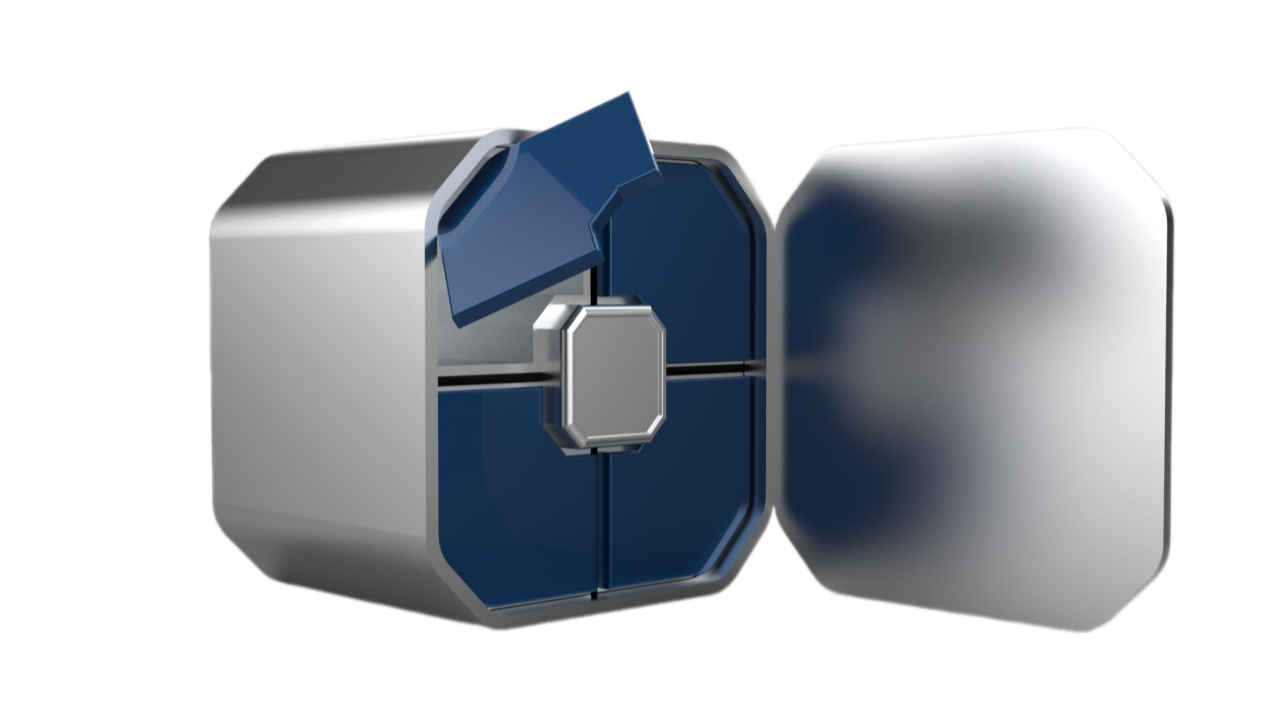

The scientific community has identified phase-change materials as transformative elements in protecting temperature-sensitive medications. This dual-material approach solves a fundamental challenge in cold chain innovation: achieving both exceptional durability and precise temperature control. The system’s robust, tamper-proof casing has undergone rigorous testing in extreme environments ranging from Arctic cold to tropical heat. Additionally, it features specialized antimicrobial coatings that prevent contamination – a vital safeguard for injectable medications. These material science advancements collectively ensure that sensitive pharmaceuticals maintain their therapeutic integrity throughout complex distribution networks.

Regulatory Science and Accurate Cold Chain Compliance

International drug regulations have changed extensively to include the most recent scientific insights into drug storage. The European Pharmacopoeia’s 2023 standard now requires the strict testing of transport systems with realistic simulation tests. These standards test performance under harsh conditions such as temperature cycling (-20°C to 40°C), prolonged 72-hour power failure, and vibration profiles simulating air and road transport conditions. Medicool not only meets but exceeds these stringent standards, with third-party verification of 99.8% temperature stability through rigorous 30-day WHO/PQS testing. This cold chain innovation is augmented by the automatic reporting capacity of the system, generating detailed audit-ready documentation whilst reducing compliance-driven administrative tasks by up to 40 hours per month (European Journal of Pharmaceutical Sciences). These capabilities are designed to solve one of the most critical issues in pharmaceutical logistics – perfect compliance while working in varied, frequently unpredictable conditions.

AI and Big Data Transforming Cold Chain Strategies

Artificial intelligence has introduced transformative capabilities to pharmaceutical logistics through advanced predictive modeling. Modern machine learning algorithms analyze vast datasets including weather patterns, traffic conditions, and historical temperature excursion data to anticipate and prevent potential issues. The effectiveness of this approach was demonstrated in a landmark 2024 Lancet Digital Health study, which found AI-optimized distribution routes reduced vaccine wastage by 62% in resource-limited regions. Medicool incorporates similar intelligent algorithms to enhance its protective capabilities. The system proactively precools units in anticipation of heatwaves, dynamically adjusts cooling power based on real-time inventory load, and can automatically reroute shipments around unexpected delays. These AI-driven features represent a quantum leap beyond traditional temperature monitoring, transitioning from passive observation to active prevention of potential problems. By harnessing the power of big data analytics, the system ensures that temperature-sensitive medications receive optimal protection throughout every stage of the supply chain, regardless of external challenges or complexities in distribution networks.

Next-Generation Packaging Design in Pharmaceutical Transport

As the demands of global pharmaceutical distribution expand, packaging has evolved from a passive container to an active, intelligent system. One of the most impactful trends in cold chain innovation is the integration of IoT sensors directly into packaging layers, enabling real-time temperature mapping at micro-zones within the container. This means that even small shifts in environment—previously invisible—are now instantly recorded and reported. When transporting temperature-sensitive medications, especially high-cost biologics and cell-based therapies, this granularity ensures every unit is tracked individually, minimizing the risk of batch-wide spoilage.

The Medicool refrigerator utilizes such micro-integrated sensor technology in its smart casing, offering superior insulation along with internal atmospheric control. Furthermore, the packaging is designed using biodegradable, medical-grade polymers that reduce environmental waste without compromising durability. These innovations ensure that temperature-sensitive medications remain viable through extended journeys, customs delays, and variable storage conditions.

Bringing Safe Medicine to Every Corner of the World

Getting life-saving medicine to people in remote or underserved areas isn’t always easy. Long travel times, rough roads, and unreliable electricity can make it hard to keep temperature-sensitive medications safe and effective. That’s why healthcare teams are now using portable solutions like the Medicool refrigerator—a smart device that keeps medicine cold even in places without stable power.

One reason these new systems work so well is because they include built-in IoT sensors. These tiny devices let doctors and health workers check the status of each shipment in real time—no matter where it is. If a delay or problem comes up, the system can help find a faster route or alert local teams before the medicine is affected. That kind of smart thinking is a big part of today’s cold chain innovation.

Conclusion

The field of pharmaceutical transport has undergone a revolution through scientific advancements like phase-change materials and IoT sensors, which now provide unprecedented protection for temperature-sensitive medications. Medicool stands as a testament to this progress, successfully translating rigorous scientific research into practical, life-saving applications. As the challenges of climate change and globalized supply chains continue to intensify, these cold chain innovations will become increasingly vital to global health infrastructure. Future developments in quantum cooling and nanotechnology promise to push these capabilities even further, potentially eliminating temperature excursions entirely. What remains constant is the fundamental mission: ensuring that every vial of medication reaches its destination with its therapeutic potential fully intact. By continuing to embrace and implement cutting-edge scientific discoveries, the healthcare community can build a distribution network that’s as reliable as it is resilient – one that consistently puts patient safety first while meeting the evolving demands of modern medicine.