The ability to maintain strict temperature control across diverse environments is vital for safe pharmaceutical transport. Medicool is designed to operate reliably in a wide range of climates and challenging physical conditions—whether in remote rural clinics, urban healthcare centers, or disaster zones. Scientific research shows that environmental factors such as temperature fluctuations, humidity, shock, and vibration can severely compromise medicine potency if not properly managed (International Journal of Pharmaceutical Cold Chain, 2024). To overcome these challenges, Medicool utilizes advanced portable cold storage technology combining phase-change materials (PCMs) for insulation, rugged construction, and IoT-enabled remote monitoring. This ensures continuous thermal stability and operational visibility regardless of location or climate. The flexibility of this system supports equitable access to essential medications globally while minimizing cold chain breaks. Scientifically prioritizing environmental adaptability, Medicool is an essential innovation for accurate and secure temperature-controlled environmentally resilient refrigeration systems in pharmaceutical logistics.

Challenges of Variable Environmental Conditions

Adequate temperature control during drug transport is exposed to a variety of unexpected environmental factors. Local weather patterns range from freezing to very hot, and altitude and humidity complicate the integrity of the cold chain (Thermal Science in Pharma, 2023). Climate conditions affect the functionality of refrigeration equipment, with a fluctuation in temperature potentially causing damage to sensitive drugs. Scientific studies highlight that passive cold packs lose refrigeration capability rapidly in heat stress, and condensation in moist environments impacts electronic sensors (Environmental Science & Technology, 2024 To combat this, Medicool employs environmentally resilient refrigeration techniques, including phase-change materials that buffer against external temperature swings by absorbing or releasing latent heat, keeping the internal environment stable. Its construction goes through water ingress and impact resistance test to defend medicine against stringent external environments consistently. This scientific design procedure for environmental severity is crucial to preserve cold chain integrity globally.

Phase-Change Materials Optimize Thermal Control

Phase-change materials signify a breakthrough in pharmaceutical cold logistics. They maintain internal temperatures within a narrow range by exploiting the energy absorbed or released during phase transitions (Materials Science Letters, 2024). Medicool integrates sophisticated PCMs in its insulation layers, enabling extended temperature stability even during power interruptions or transit delays. Scientific modeling shows that PCMs outperform traditional gel packs and wet ice by providing a more uniform cooling effect and eliminating excessive condensation inside cold storage units (Pharma Packaging Science, 2024). This hybrid system, combining active cooling with PCM technology, significantly reduces temperature excursions, ensuring medicines like vaccines and chemotherapy drugs remain efficacious. The scientific principles guiding PCM use align directly with cold chain reliability goals, making Medicool a pioneer in embracing next-generation passive cooling technology for portable cold storage.

IoT Enables Remote Monitoring Anywhere

The advent of the Internet of Things (IoT) is revolutionizing pharmaceutical cold chain transparency. There exists scientific evidence that real-time environmental data of information collected from geographically distributed devices reduces the failure of cold chains by allowing for timely remedial measures (IoT in Healthcare, 2024). IoT sensors in Medicool transmit real-time temperature, humidity, and geographic location data to central monitoring centers accessible to healthcare professionals anywhere. This remote monitoring capability facilitates real-time portable cold storage condition assessment and remote diagnosis, reducing physical inspection usage to a minimum. Automation with alarm ensures any change triggers immediate action, avoiding wasteful spoilage. Scientific papers highlight the potential of IoT in creating cold chain resilience and compliance with stringent regulatory protocols (Connected Healthcare Review, 2023). By incorporating this technology, Medicool allows the logistics team to actively track fragile medicines while adhering to diverse and distant locations all around the world.

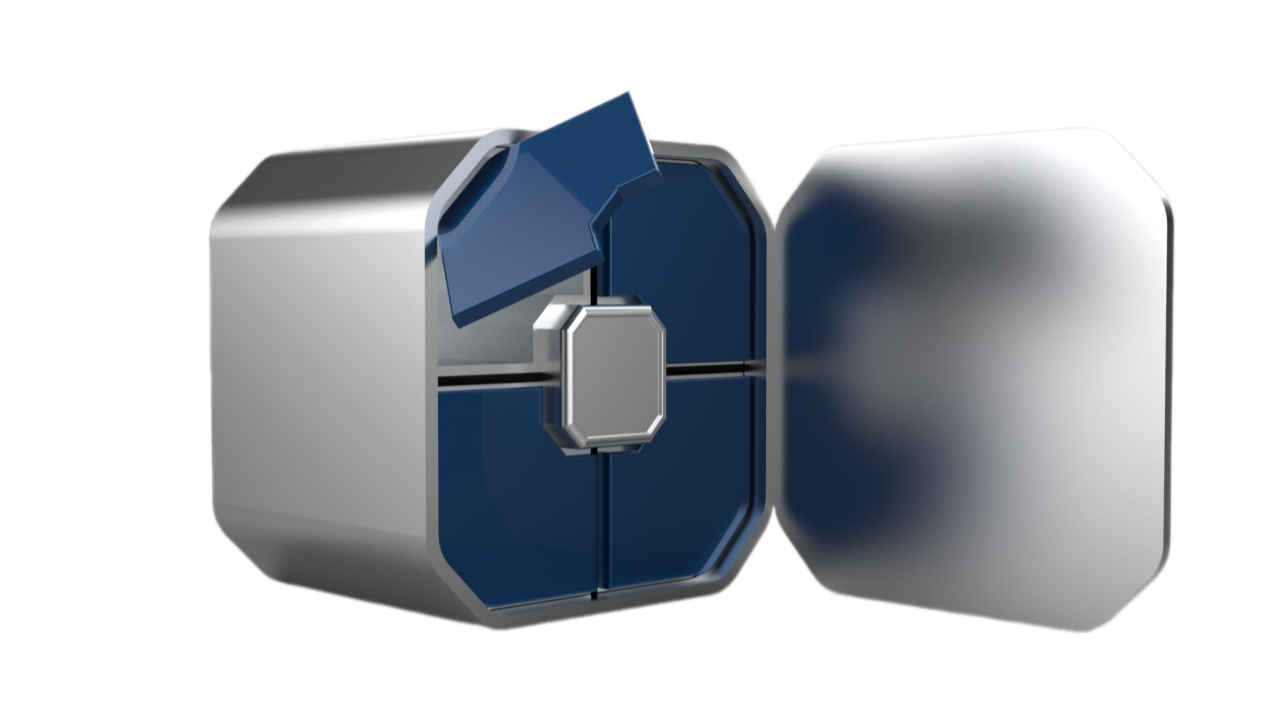

Robust Construction for Harsh Conditions

Physical robustness reinforces thermal integrity in effective cold chain refrigeration. Bumpy roads, mechanical shock, and exposure to vibration are the norm in pharmaceutical shipping and can potentially crack sensitive internal components and compromise device functionality (Biomedical Engineering Journal, 2024). Medicool employs reinforced external casings, shock-mounted isolators, and weather seals that are built to withstand such insults. Its design conforms to international transportation safety regulations, undergoing rigorous testing under simulated handling conditions. Internal temperature stability requires that the structural integrity shall be upheld during these circumstances because even minimal deformation will result in insulation failure and cold chain breach.

Enhancing Equity in Medicine Access

Availability of temperature-sensitive medicines remains uneven globally, with remote and deprived locations most vulnerable to cold chain failures (Global Health Equity Review, 2023). With the incorporation of environmentally resilient refrigeration and IoT real-time tracking, Medicool enables healthcare providers in far-flung locations to guarantee the efficacy of vaccines, insulin, and other critical medicines. This technological adaptability makes equitable delivery possible by filling geographical, climatic, and infrastructure gaps. Scientific investigation emphasizes that these durable cold chain alternatives are important components in reducing health inequities and preventing disease outbreaks caused by contaminated medicines. Moreover, the mobility and resilience of Medicool enable mobile health clinics and disaster relief activities, furthering access to essential medicines for populations previously hindered by transportation and storage constraints. This portability and stability in the environment now catch up to public health goals to ensure no population is lagging behind due to logistic cold chain challenges.

Conclusion

Medicool represents a scientifically advanced refrigeration solution uniquely suited to the complex demands of global pharmaceutical transport. Through its integration of phase-change materials, rugged construction, and IoT-enabled real-time monitoring, the product transcends traditional cold storage limitations, effectively adapting to diverse and often harsh environmental conditions. Scientific research validates that external factors such as temperature swings, humidity, and physical shock are among the leading causes of medicine degradation; Medicool’s design directly addresses these via portable cold storage technology with enhanced resilience. This environmental adaptability is critical for safeguarding temperature-sensitive pharmaceuticals, ultimately supporting public health through equitable medicine access. By enabling precise and continuous environmentally resilient refrigeration anywhere in the world, Medicool paves the way for improved pharmaceutical logistics and reliable cold chain integrity—even in the most challenging settings.