Across the world’s healthcare networks now, temperature-sensitive medications delivery is mission critical. These medications—vaccines, insulin, and cancer treatments—are required to be held at very precise temperatures at every juncture of delivery. Even a minute variation in temperature can result in total drug failure, endangering patients and money down the drain. To counter this, cold chain logistics is evolving. New technologies like phase-change materials (PCMs), real-time tracking, and data analysis are making drug delivery safe. Medicool, a smart delivery refrigerator, incorporates these technologies in products to ensure safety of medicine. Much more critical than the product, however, is the science. This blog addresses the ways research is impacting future biopharmaceutical logistics, regulatory engineering, and cold-chain performance. We delve deeply into how wiser systems—and wiser materials—are getting drugs safer and people healthier.

Why Constant Temperature Matters

Keeping temperature-sensitive medications within the proper range is not an option—it’s required. Most vaccines, insulin formulations, and biologic medicines must be stored between 2°C and 8°C. When temperature-sensitive medications are exposed to room temperature for only 30 minutes, its effectiveness diminishes (International Journal of Pharmaceutics, 2023). In cold chain logistics, sensors and alarms are used to detect these shifts in real time. It is there that smart systems like Medicool come in, giving constant surveillance for identifying divergences before they become disasters.

But it’s not just watching a thermometer. Scientists in biopharmaceutical logistics now model the transfer of heat through different kinds of containers. Understanding how heat flows around boxes, pallets, and trucks enables manufacturers to choose better shipping methods. This research improves both transport and storage quality, safeguarding temperature-sensitive medications until they are used. As complexity increases in cold chain logistics, advanced designs and enhanced real-time information will become the new standard in biopharmaceutical logistics.

Smart Cooling and Sensor Technology

One of the most significant innovations in cold chain logistics is smart cooling. Instead of relying on passive containers, many companies now use active refrigeration systems with real-time controls. Medicool is one such system, providing active cooling with real-time temperature feedback. This allows transport teams to respond instantly to risks—even in remote areas or extreme weather.

In parallel, scientists in biopharmaceutical logistics are developing improved sensors that can track humidity, vibration, and shock in addition to temperature. These sensors provide a complete picture of product conditions throughout the journey. Once collected, this data is fed into data analytics systems that alert operators before a failure happens. This proactive approach is drastically reducing spoilage.

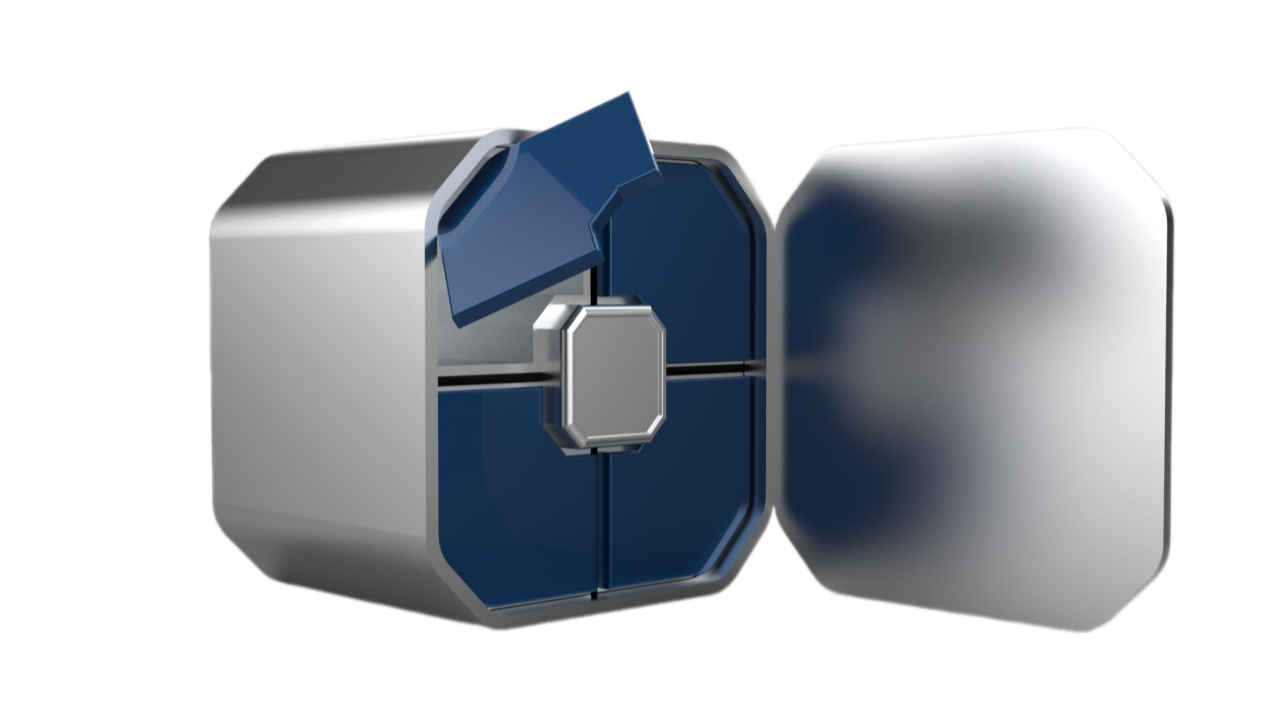

Every piece of this system—from insulated materials to Medicool’s digital locks—supports safer, smarter transportation. The combination of sensor science, container design, and data analytics is making cold chain logistics more efficient and more accurate than ever before.

Watching the Medicine, Not Just the Box

Today’s cold chain logistics is much beyond truck monitoring—it’s almost monitoring the drug itself now. New biosensors can detect molecular integrity in vials of temperature-sensitive medications. They can track for initial degradation indications like pH shifts or protein damage (Nature Biomedical Engineering, 2024). Biosensors completely change biopharmaceutical logistics, especially when handling expensive gene therapies or cell-based drugs.

When coupled with systems like Medicool, these biosensors provide end-to-end visibility of drug condition. That is, companies no longer have to take an educated guess as to whether a shipment was safe—they know. In fact, regulatory authorities are starting to demand this level of visibility. For vaccines, cancer drugs, and biologics, biosensor integration into cold chain logistics is becoming a norm for high-value temperature-sensitive medications.

Regulation, Compliance, and Scientific Control

Regulatory agencies like the FDA and Health Canada are making strict demands on cold chain logistics. These standards require full traceability and compliance with storage protocols. To meet these demands, companies are turning to systems that combine science, real-time monitoring, and secure tracking. Solutions like Medicool offer automated reports, secure access logs, and fault detection features that help meet these standards.

But beyond the technology, it’s about building systems that are audit-ready and science-based. In biopharmaceutical logistics, this means having validated temperature logs, certified sensors, and secure cloud reporting. And behind all of that is data analytics—which aggregates and organizes data for easy compliance and trend analysis.

Many drug manufacturers are redesigning their logistics workflows to integrate real-time science into every stage. Whether it’s the packaging design, the route choice, or the failure analysis, everything is being driven by intelligent systems. This is making cold chain logistics more compliant, transparent, and efficient.

Predictive Logistics Through Data Science

The next generation of cold chain logistics is forecasting—not reacting. With robust data analysis, companies can now predict risk and make changes accordingly before problems occur. For instance, if there is a lane that has had a history of temperature variations, the system can suggest an alternative. If a shipper has been consistently late, they can be identified and swapped out.

Medicool makes this vision possible through the collection of accurate transport data, from in-vehicle temperature to environmental conditions. These data are input into advanced biopharmaceutical logistics software systems that make improved decisions on a daily basis. Next, more drugs are not wasted, fewer patients are affected, and fewer resources are lost.

Predictive analytics allows for automated risk management. With machine learning, data analytic tools can search thousands of data points and raise red flags humans would never see. Combined with real-world sensors and cloud platforms, cold chain logistics is no longer a reactive system but rather a proactive system. And with technology tools like Medicool leading the way, the future becomes even more stable and secure.

Conclusion

As the healthcare universe advances to increasingly sophisticated therapies and international drug delivery, cold chain logistics needs to adapt. It’s no longer acceptable to “hope” medications get there safely. Success today is derived from science—improved sensors, smarter systems, and more profound data analytics. Whether it’s anticipating risks, preventing delays, or keeping perfect temperature, intelligent delivery counts. Technologies like Medicool are demonstrating what can be achieved when brilliant design intersects with scientific strategy.

In biopharmaceutical logistics, the protection of a shipment protects lives. That is why innovation matters. Every step of the process—from storage to transportation to delivery—must be accurate, connected, and authenticated. With tools like Medicool, supported by the power of data analysis, the future of healthcare delivery is brighter, safer, and more efficient.